Recycled plastic bottles are used to make carpet, clothing and even auto parts.

Laboratory vacuum systems are energy-intensive but essential for various tasks in the lab, including filtration, sample aspiration, and desiccation. Weill Cornell facilities rely on centralized vacuum pumps located in mechanical rooms, which are piped to various areas, providing vacuum service where it’s needed. The pumps are maintained by our dedicated Facilities & Campus Services (FCS) team. When they receive a work order, the problem is usually the nozzle getting clogged. In this case, they need to clean it or replace it. The way we use these systems can significantly impact energy consumption, the system’s capacity, and the longevity of the equipment. By following vacuum systems’ best practices, we can help preserve it for everyone.

House vacuum system’s pumps (left); House vacuum system taps (middle and right)

How to Properly Use a Vacuum Line

- Use the correct tubing that can support the vacuum without collapsing (hard plastic).

- Don’t use rubber tubes as it deteriorates, generating particles that get sucked into the vacuum line.

- Use properly fitting stoppers to allow for good suction.

- Replace tubes and stoppers regularly.

Important: Never allow chemicals, fluids, vapors, or debris to enter the vacuum lines. These materials can cause blockages and damage the system’s pumps, leading to costly repairs and downtime.

Tissue Culture Aspiration:

- Use aspiration traps: Always empty your suction flask and trap to avoid overfilling.

- Install HEPA filters: Place a High-Efficiency Particulate Air (HEPA) filter in between your flask and the vacuum line.

- Disinfect: For tissue culture work or when handling potentially infectious fluids, add bleach to the suction flask or other suitable disinfectant.

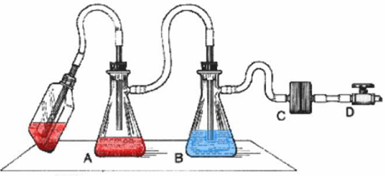

A = Aspiration flask – collects contaminated fluids (tissue culture media, stains, fixative) into a decontamination solution such as 10% bleach.

B = Overflow trap - Collects overflown fluids, with the collection tube submerged in liquid to minimize aerosols.

C = HEPA filter – In-line filter prevents contamination of vacuum.

D = Valve to house vacuum system

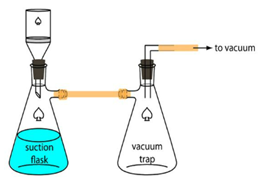

Suction filtration with Buchner:

- Use aspiration traps: Always empty your suction flask and trap after every use to avoid overfilling.

- If you’re working with volatile materials, set up a cold trap in-line after a suction flask, to condense as much of the vapor as possible before it reaches the vacuum line.

The Importance of Switching Off Your Vacuum Valve

The vacuum system’s equipment is designed to accommodate a certain number of concurrent users. However, if labs leave their vacuum valves open continuously, the system can have trouble keeping up with demand. This results in weaker vacuum pressure or, in the worst-case scenario, a complete vacuum shutdown for the entire building.

To help prevent this, please switch off your vacuum valve after each use.

By doing so, you can:

- Reduce energy consumption

- Preserve vacuum system capacity for all users

- Extend the lifespan of the equipment

What to Do If the Vacuum Line Isn’t Working Properly

1. Check the setup: Check for issues with the apparatus, such as improper tubing (make sure the tubing is thick enough not to collapse when the vacuum is on), leaks in the tubing, or flask stopper.

2. Contact facilities: If there are no obvious issues with your apparatus setup or if you notice that the tap valve is hard to open, submit a work order for assistance.

Note: if there is a clog in the line or valve, the entire valve system may need to be replaced.