Recycling 1 ton of paper saves 17 trees, 7000 gallons of water, 3.3 cubic yards of landfill space, 2 barrels of oil, enough energy to power a house for 6 months.

Ultra-low temperature freezers (ULTs), commonly referred to as -80 freezers, are some of the most energy-intensive plug-load equipment utilized in labs. They often consume as much energy as the average American household. For this reason, it is important to practice proper freezer maintenance to minimize a lab’s carbon footprint. ULTs should be serviced and defrosted annually to maintain efficiency and increase operational life. Yearly defrosting reduces the likelyhood of freezer failure and avoids samples from getting buried in the ice and disappear from the radar. Freezer door seals should be brushed regularly in order to be kept free of ice. Labs may consider outsourcing tasks, such as a yearly freezer defrost, battery change, or filter cleaning, to an outside vendor if regular maintenance is not possible in-house. Many labs on campus contract with Cryostar.

Helpful Tips for Minimizing Energy Consumption and Extending the Life of ULTs

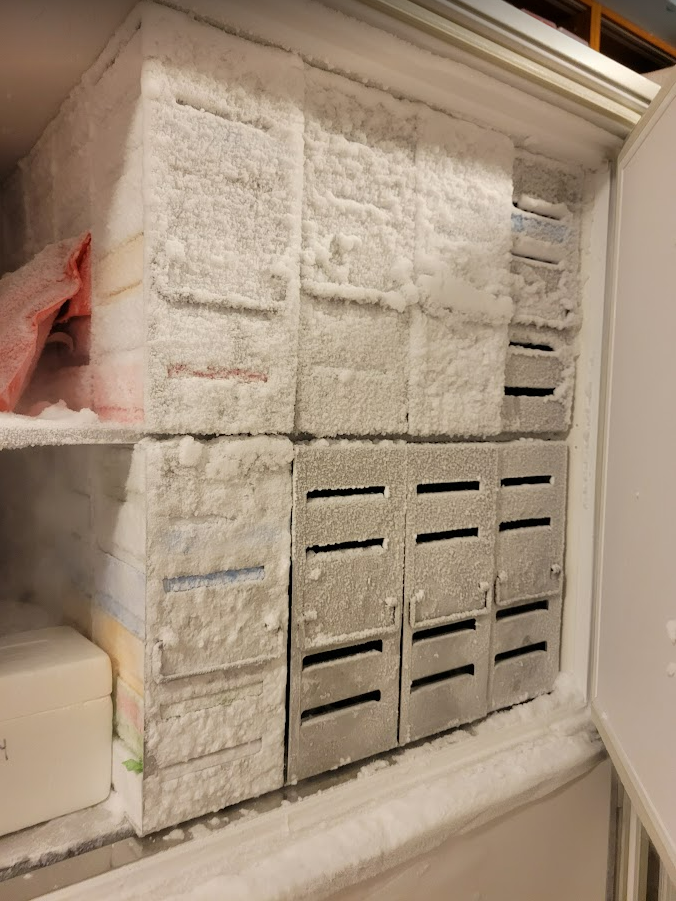

Racks inside an ultra-low temperature freezer.

- Minimize time with the door open. Organizing the freezer content and keeping an updated inventory will make it easier to find samples quickly.

- Regularly clean out the content of existing units to accommodate new samples or sharing freezer space with a neighboring lab.

- Provide a clearance of at least six inches to both sides and the back of the unit, and eight inches should be available on top. While tempting, avoid stacking boxes on top of the freezer. Units need sufficient clearance to be able to “breathe” and reject heat effectively to the surrounding area.

- Purchase an efficient model, when buying a new freezer, and ask your vendor’s rep for ENERGY STAR-rated options.

- "Chill up" your ULT to -70°C to save up to 30-40% of energy. Until 15 years ago, the maximum temperature that a freezer could reach was -70°C. Researchers started setting freezers to -80°C just because technological advancement allowed us to do so. Click here to learn more.

- Participate in the yearly International Freezer Challenge to make your freezer maintenance competitive and fun.

Yearly Freezer Cleanout

Get started:

- Inform the lab of the upcoming cleanout in advance so teams can plan accordingly.

- Identify backup/provisional storage.

- Take the opportunity to clean up and discard old, unnecessary, or ruined samples and update the sample inventory. Plan to clearly label all the samples and post a freezer map on the freezer door.

Procedure:

- Move the freezer content to provisional storage.

- Ensure necessary items are ready before you start defrosting:

- Heavy duty/cold temperature gloves

- Ice scraper and brush

- Absorbing pads/cloths for the floor (to reduce slip hazard), possibly made of reusable material

- Bucket to collect the built-up ice

- Switch off the freezer and disconnect the plug.

- With the help of an ice scraper, brush, and a bucket, remove the excess ice built up. Start on the seal on and around doors, then inside the shelves. Be careful to avoid tearing the rubber seals and gaskets.

- Clean gaskets with a soft brush or dry cloth to maintain a good seal.

- Let the remaining ice melt.

- Wipe down the excess water.

- Disinfect the defrosted freezer.

- Let it dry.

- Clean filters and coils.

- Reconnect the unit to the power and switch it on.

- Wait for the freezer to reach the set temperature before moving the material back from the provisional storage.